Breakthrough in Recyclable Coffee Packaging

Club Coffee, a leading coffee roaster and packaging solutions provider in Canada, has introduced the AromaPak® family of sustainable and innovative packaging solutions for whole bean and ground coffee. The new packaging builds on Club Coffee’s success with the certified commercially compostable Purpod100® single-serve coffee pod. Research showed paper-based packaging to be the most consumer-acceptable solution for whole bean and ground coffee packaging.

During a trade show in 2019, Club Coffee’s development team appreciated the potential of paper-based canisters formed from flat paperboard. AR Packaging Group, which had filed multiple patents for its Boardio technology, was purchased by Graphic Packaging International in 2022. The joint project with Club Coffee was a great opportunity, but also came with challenges.

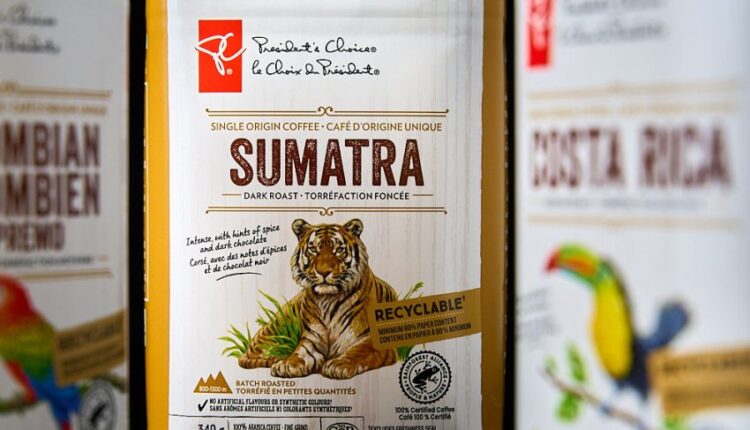

During the COVID-19 pandemic, Club Coffee bought and installed equipment, commercialized the AromaPak® featuring Boardio® technology, and launched major brands in 500 days. The speed to market enabled Canadian retailer Loblaw Companies Ltd. to announce the new format in April 2022, stating it was “overhauling the coffee aisle by replacing unrecyclable packaging with a first-of-its-kind-in-Canada paper-based solution.”

Ensuring recyclability and sustainability impacts were key elements in the overall innovation strategy. The Club Coffee team worked with How2Recycle to earn AromaPak™ a “widely recyclable” designation, meaning the packaging material is acceptable in a minimum of 60% of curbside recycling programs in Canadian and American communities. The new format results in 91% less carbon emissions per year compared to steel cans, 50% reduction in plastic use compared to bags, and 43% reduction in injection-molded plastic cans.

The packaging of coffee products is a complex process that involves the use of paper/foil laminate rolls to create four flat blanks: body, lid, easy-peel membrane, and base. The membrane is made of paperboard and foil and has a one-way degassing valve. The bodies are printed offset and partially perforated near the top, allowing consumers to open the finished canister with a small strip of unperforated material that serves as a hinged reclose feature.

Graphic Packaging sends the material to Club Coffee’s Toronto facility, which processes smaller and larger canisters. Both lines include a Spee-Dee auger filler and are designed with a small footprint for high-speed case and tray packaging at 125 canisters/min. The forming and filling operation is essentially the same, with a body blank picked by vacuum cups from a magazine and indexed into a station where it is wrapped around a mandrel and turned into a cylinder through application of roll-fed foil with sealant on it.

Canisters are then transferred from a horizontal to a vertical orientation and placed on a tool from which they are pushed into indexing devices, enabling the membrane to be picked by vacuum cups from a magazine feed and placed inside the body for induction sealing in place. They advance to the next station where a similar pick-and-place method inserts and induction-seals the lid of the canister, which is then curled.

The paperboard canister is placed between existing rigid and flexible containers, requiring close work with Morrison Container Handling on feed screws and other container handling parts to ensure gentle handling. The canisters are flushed with nitrogen, filled, and vibrated to ensure adequate head space before induction sealing of the bases, followed by curling the base rim.

A twist upender from AFA Systems reorients canisters from lid down to lid up before they enter a CP-WCP Wraparound case and AFA tray packer. After passing through a Mettler-Toledo X-ray metal detector, a servo-driven starwheel turner ensures controlled turns of each canister. When enough canisters are in place, a side-shift mechanism with gantry robot pushes them onto a partially erected case or tray. Another gantry robot picks up corrugated blanks and can fold the top flap of the case or tray 90 degrees.

The case/tray packer has the flexibility to run both wraparound cases and corrugated trays, with the only change being changing the end effector on the gantry robot case former/tray erector. Palletizing of cases and trays is currently done manually, but an automated palletizer is on track for installation.

Read More @ Packaging World

Source: Coffee Talk