How to start a micro roastery

Micro roasters, often defined as companies that sell less than 100,000 lbs (around 45,300kg) of coffee annually, typically focus on sourcing specialty coffees from diverse regions. By working with smaller volumes, they can highlight unique flavour profiles and offer a more direct connection to origin, making high-quality coffee more accessible to a wider audience.

As such, a passion for coffee quality and traceability is essential to starting a successful micro roastery. However, operators also need to take a pragmatic approach to managing margins and cost efficiency – especially while business costs and coffee prices are rising.

To learn more, I spoke to Donovan Albert, the owner and CEO of Anchor & Tree Coffee Roasting Co. in California, US, about how the company has used Bellwether Coffee machines to scale.

You may also like our article on how micro roasters paved the way for in-store roasting.

What are the first steps when opening a micro roastery?

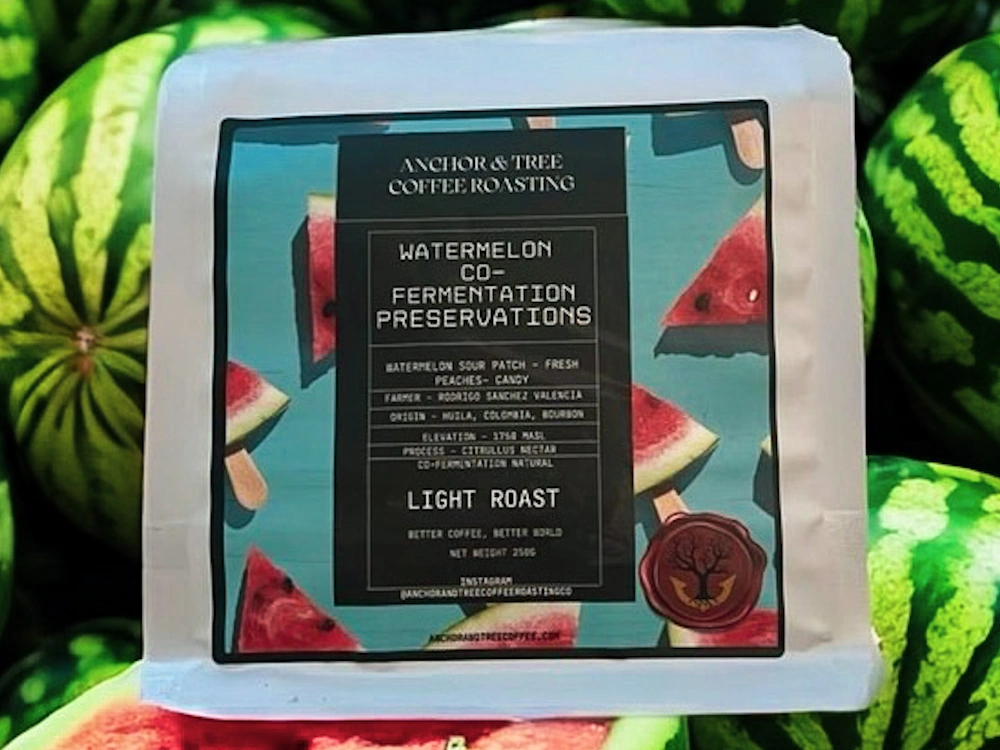

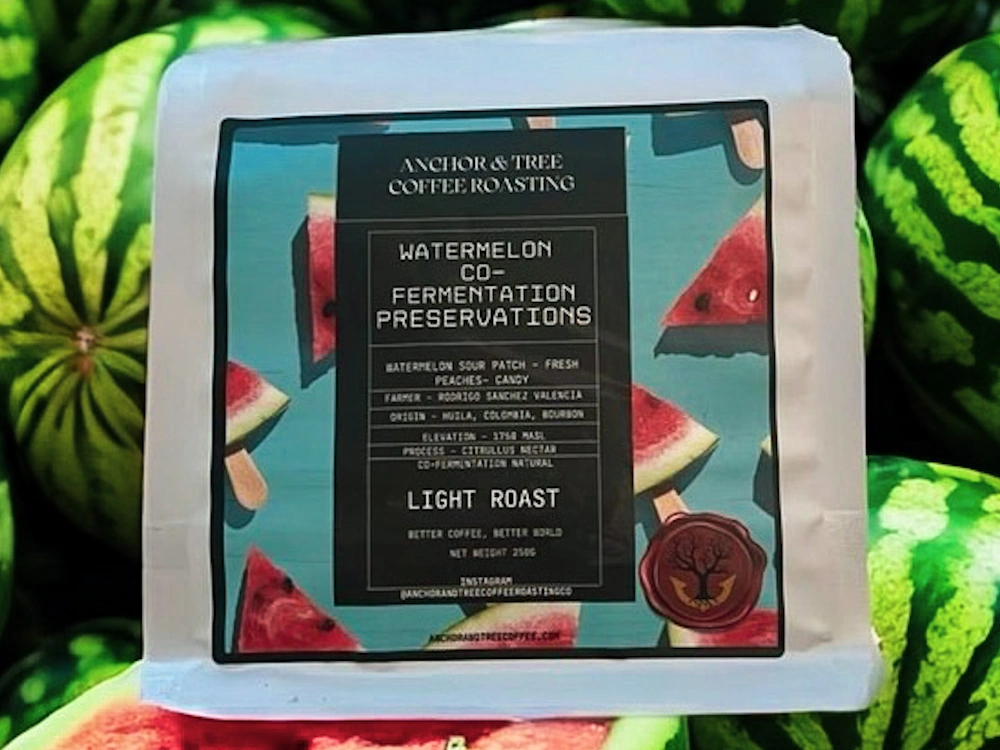

“Micro roasting has become incredibly popular in recent years primarily due to the ability to control the outcome by roasting coffee in smaller batches,” says Donovan Albert, the owner and CEO of Anchor & Tree Coffee Roasting Co. in Sacramento, California. “You can control the heat application more precisely, offering more consistent flavour profiles and reducing the variables within the batches.”

These coffee offerings provided customers with something new and offered roasters a point of differentiation in an increasingly competitive market. But when choosing to start a micro roastery or roast coffee in-store, decisions can quickly become overwhelming, so it’s important to address some of the essentials first.

“The first thing to think about is finding a machine that aligns with your mission and long-term goals,” Donovan explains. “You need to find a roaster that you have the knowledge base for, and that will allow you to roast the types of coffee that you want.”

Today’s coffee consumers are increasingly looking for businesses that prioritise sustainability. According to a recent study from the International Institute for Sustainable Development, 43% of coffee consumers say they are influenced by “ethical, environmentally friendly, or socially responsible coffee options”, meaning businesses have an opportunity to tap into growing demand and differentiate themselves.

From packaging to green coffee buying to roastery operations, more coffee companies than ever are claiming their practices and products place environmental, social, and economic responsibilities at the forefront.

Even more pertinently, the worsening climate crisis is having a growing impact on the coffee value chain. By 2050, the amount of land available to grow high-quality arabica is estimated to halve, threatening the future of the industry as we know it.

This makes the equipment you choose, which contributes to the industry’s carbon emissions, all the more important. Donovan says all-electric roasters like Bellwether can reduce roasters’ carbon footprint by up to 87% compared to gas-powered alternatives. Additionally, the Bellwether Green Coffee Marketplace gives them access to ethically sourced, transparently traded green coffee – eliminating the guesswork from responsible sourcing.

“I wanted a roaster that was sustainable and eco-friendly without compromising the quality of our coffee,” Donovan tells me. “With my background in roasting software education, I felt like the Bellwether Shop Roaster was a perfect fit; it’s electric, ventless, automatic, and eliminates up to 90% of carbon emissions from the roasting process.”

Sustainability isn’t just an environmental concern; it’s also a cost-saving measure. With electric machines, roasters can eliminate fuel costs, reduce waste, and streamline operations, all of which contribute to a healthier bottom line.

Scaling a micro roastery for long-term business growth

Micro roasters must maintain consistency and remain true to their value proposition to ensure consumer loyalty, presenting ongoing challenges. Looking ahead, scaling operations can also pose a major hurdle to navigate.

To overcome this, it’s important to set realistic goals and have a clear vision of what the business wants to achieve in a given time frame. Some questions for owners and operators to consider include:

- Do you want to take on wholesale clients?

- Is it a goal to branch out and open multiple outlets in the same city or across various geographies?

- Do you eventually want to increase roasting capacity and move to a larger commercial space?

“Everything won’t work the way you want it to at first, so being patient is extremely important,” Donovon says. “Hone in on one side of the business first instead of stretching yourself thin, focusing on many different things at the same time.”

Wholesale roasted coffee can cost up to 50% more than roasting in-house. Businesses that invest in their own roasting equipment not only control their costs but also open up new revenue streams, such as wholesale accounts and private-label offerings.

“If you’re new to roasting, I would first recommend finding a co-roasting space to learn as much as you can and take roasting classes,” Donovan adds. “This will help you decide what type of roaster you want to become and what type of coffees you want to sell.”

Choosing the right roasting equipment for efficiency & growth

One of the key considerations for micro roasters is selecting equipment that can grow with their business. Many small-batch roasters start with a traditional gas roaster, only to realise that scaling requires additional infrastructure like gas lines, staffing, and operational complexity.

Donovan says the Bellwether Shop Roaster, awarded Best New Product by the Specialty Coffee Association at World of Coffee Copenhagen in June 2024, eliminates these challenges with its electric, ventless, and fully automated design.

He adds that the Countertop Roaster has a 1.5kg capacity per batch and can roast up to four batches per hour, making it ideal for small-scale, on-demand roasting. The Continuous Roasting Upgrade, meanwhile, has an autoloading system capable of roasting up to 200kg (440lbs) per week, offering up to 13 continuous roasts, allowing businesses to scale volumes should they choose to.

“The Shop Roaster’s continuous roasting option allows me to free up my bandwidth to focus on other tasks, removing the need for constant monitoring and intervention,” Donovan adds. “It’s been a game-changer for our business growth.”

Streamlining operations has never been more important for coffee businesses looking to scale or maintain current roasting volumes. With a high and volatile C price, rising inflation, and growing interest rates all squeezing already-thin margins, roasters are being pushed to manage costs more effectively than ever before.

Automation has emerged as a viable way for operators to replicate human-driven processes that free up time and reduce error, minimising costs in the long run. For example, the Bellwether Shop Roaster’s Continuous Roasting Upgrade features a green coffee autoloader and freestanding base roasted coffee storage unit, allowing roasters to increase productivity without increasing labour costs.

Why equipment plays an integral role in growth

Smaller batch sizes can help micro roasters offer more variety to their customers, allowing operators to switch between different coffees quickly. However, at the same time, micro roasters may seek to scale operations in the future, and their equipment needs to account for this.

Donovan explains that machines like Bellwether allow micro roasters to expand efficiently without increasing overhead. The Continuous Roasting Upgrade means businesses can meet demand while keeping roasting time to a minimum. Additionally, cost savings from in-house roasting create new opportunities, such as investing in retail expansion, marketing, or wholesale partnerships.

“If you want to become a wholesaler or have a café, focus on one thing first: Grow with an accurate profit margin and generate a recurring income,” Donovan says. “Build your wholesale programme to a point where it can be sustainable by itself with a team running it, then branch off and open the café you want. Most people try to do all this at once, and it usually never works.”

Starting roasting operations empowers businesses to make high-quality, freshly roasted coffee more accessible while reducing upfront costs. This not only increases profitability but also creates opportunities to expand into wholesale and diversify revenue streams. By removing the barriers of scale and experience, micro roasters can take control of quality and sustainability from day one.

A passion for coffee quality and traceability is essential to starting a successful micro roastery, but operators also need to take a pragmatic approach.

Roasters need to define their mission and vision, determine the type of business they want to be, and set realistic goals. Picking the right equipment is essential to success, allowing roasters to maintain operations or scale volumes in the future.

Enjoyed this? Then read our article on how the micro roaster market is evolving.

Photo credits: Bellwether Coffee

Perfect Daily Grind

Please note: Bellwether Coffee is a sponsor of Perfect Daily Grind.

Want to read more articles like this? Sign up for our newsletter!

Source: Perfect Daily Grind